2009-12-01

2009-04-20

Heating and Cooling from The Ground Up

2009-04-19

Climatic Warming

Risk of Action and Inaction

2009-04-18

Solar Thermal Power Systems

Because the fossil fuels used to run our generators are being rapidly depleted, we must find new methods of producing electricity. While water and wind power are already in use, the most promising source of electricity may be something Earth has more than enough of— sunlight.

At Sandia National Laboratories, in Albuquerque, New Mexico, engineers are working to harness the sun's energy to generate electricity. One of their projects involves the Stirling engine, a machine that was invented by Robert Stirling in 1816. A large, dish-shaped mirror is used to reflect sunlight onto an absorber, which collects the energy and uses it to increase the internal energy of helium inside the engine. At that point, the engine works much like an automobile engine. The heated helium gas is used to move a piston, but instead of spinning a set of wheels, this piston turns an electric generator.

The Stirling engine operates very efficiently; it holds a world record for converting solar energy into electricity. It is ideal for remote locations, where normal power lines cannot be run, or for power-specific devices, such as water pumps for agricultural purposes.

Sandia is also developing a solar power plant that uses the sun's energy to melt large quantities of salt. The energy transferred as heat from the salt is then used to generate steam, which can turn a turbine to make electricity.

Turbine Rotor

In this rotor you can find many turbine blade that circulate on the body.

Turbine Blade in The Row.

Single Turbine Blade

Once ago we manufactur about 1000 turbine blade for steam turbine. For detail manufacturing you can contact me at +62 818 436 859. We offer you to make that part with good price.

2009-04-17

Material Development

After some experiment SS400 can achieve surface hardness 70HRc and the core still have toughness characteristic. That can be apply for spring steel or even cutting tool material. He use carbon from animal bone for medium for carburizing process.

After some experiment SS400 can achieve surface hardness 70HRc and the core still have toughness characteristic. That can be apply for spring steel or even cutting tool material. He use carbon from animal bone for medium for carburizing process. 2009-04-14

Die & Mould Sector

The business of producing dies and moulds is a highly integrative effort involving machines, tools, software, and people.

Making moulds and dies is not just about cutting tools and scraping metal from work-blocks, but a careful combination of the process drivers. It is a team effort on the part of everybody that has enabled the die/mould making sector to face up to the challenge of demands of diverse natures from a slew of manufacturing sectors, and come out trumps. However, there are some loose ends still to be tied.Apart from integrated effort, individual initiatives in changing process setups in

mould shops, opting for high-performance tools etc, have also been instrumental in the success of the die/mould makers the world over.

Market Growth Scenarios

Many die/mould makers are keen on expanding their markets to other parts of the world, such as Southeast Asia and China. One reason is the burgeoning automotive sector, which consumes a hefty amount of dies/moulds for the fabrication of automotive parts. That is good news for die/mould makers in Asia and Australasia, as well as those in the West who have a market in Asia.

While on Asia, one cannot miss India. The ever-burgeoning auto components sector, whose exports rely a lot on good quality moulds and dies (zinc and aluminium alloy die-casting units are doing big business selling carburettors, automotive door locks, etc), on the one hand, and the cash-rich stainless steel utensils sector on the other hand, are driving the growth in the domestic die/mould industry. The dies used by the utensil manufacturers are typically those employed for bending, drawing and deep drawing operations. Considering the volumes of stainless steel kitchenware which emerge out of shops in the country, and also keeping in mind the tremendous export potential that these products have, this sector is certain to be a sustained area of

demand for die makers. A look at the variety of utensils – shapes and sizes – would set the mind racing to the innumerable dies that may have been employed to fashion them.

The small-scale Indian entrepreneurs who specialise in die-making, are now no longer plagued by the lack of finances.

Low-interest loans are there for the asking; for investments in technological upgrading at the die-making shops.

CAD/CAM software and CNC machines are now affordable, and the quality of these dies and the life thereof will also be improving, resulting in timely fulfillment of export orders.

Material Developments

For the plastics sector, it has been a case of ‘aluminium to the rescue’. Steel moulds are still common, when there is not much pressure on delivery times on the mould maker, and when the end-user is a small-scale manufacturer, whose output is limited by a modest demand for his products. However, when the demand in the marketplace increases, the moulds will have to be overworked.

Cost and functional superiority would be the guiding criteria that the mould maker would base his decisions on. The result: the steel may have to go, making way for aluminium alloys. The addition of magnesium, copper, zinc and silicon in varying proportions to aluminium, enhances its functional properties (while being machined, as well as while being used to mould the end products). The trigger here is the demand for a mould which will increase the number of products moulded every day.

There have been total transitions of late, from steel-mould-making setups to aluminium-mould-making ones. Toolcraft Plastics of the UK is one of the latest to be bowled over by the advantages of aluminium. The said company incidentally, has an in-house mould-making unit, the moulds from which are employed not just for its own plastics production, but also sold in the market to other plastics producers. Early this year, TPSL managed to bring down its production time considerably, while cutting down the cost by 30 percent.

This tallies with Alcan’s (the leading aluminium producer in the world) economic analysis of the mould construction and utilisation phases, for aluminium (the Certal brand) and steel (Ck45 steel). Aluminium is costlier than steel by approximately 60 percent, but the machining and energy costs are less than half of those for steel. This more than offsets the extra costs incurred while purchasing the material. For a given weight of material, for every steel mould, 2-3

similar aluminium moulds can be made.

HITACHI is one company that has been focusing developing new tool geometries, inserts and cutting tool materials for high performance cutting (HPC) of dies and moulds. These developments aim to improve performance, productivity and profitability. The introduction of the tools for very high feed, plungers for high productivity in machining deep cavities, and

drills for high efficiency in drilling are some examples.

Optimisation of the insert and chipformer geometry in milling, drilling, and profiling improves accuracy of the machined surface, provides more tool life, reduces cutting forces and vibration and makes fast metal removal (FMR) possible. For roughing applications on dies and moulds, new tooling technologies such as plunging tools, ramp-down tools or milling cutters with helical cutting edge inserts like are used.

Helical inserts have been developed for shouldering, facing, slotting and profiling This type of tool solves the main

Helical inserts have been developed for shouldering, facing, slotting and profiling This type of tool solves the maingeometrical disadvantages which are the lack of workpiece side wall straightness, flatness, and perpendicularity of a

straight cutting edge insert positioned with a positive axial angle. Inserts are made of submicron substrate with improved toughness and hardness, better resistance to chipping, and high wear resistance.

The TiCN coated tools are recommended for most of the standard applications in machining alloy steel and tool steel materials. The TiAlN coated tool is an excellent grade for hard machining, dry cutting, and on high-temp alloys. The machining of dies and moulds made of alloy-steel in the soft and hardened state with the new PVD-TiAlN coated tools improves tool life significantly.

• Facing With Very High Feed

For facing with very high feed rates HITACHI has developed a special super radius-shaped positive insert having a cutting-edge configuration with a very large radius. In this unique FEEDMILL geometry the relative small insert design with positive rake angles is recommended for small depth of cuts and very high feeds providing easy chip flow, lower cutting forces and a stable operation. The tools can be used for fast metal removal in machining dies and moulds with deep cavities with large overhangs at very high feeds, up to 3.5 mm per tooth.

For facing with very high feed rates HITACHI has developed a special super radius-shaped positive insert having a cutting-edge configuration with a very large radius. In this unique FEEDMILL geometry the relative small insert design with positive rake angles is recommended for small depth of cuts and very high feeds providing easy chip flow, lower cutting forces and a stable operation. The tools can be used for fast metal removal in machining dies and moulds with deep cavities with large overhangs at very high feeds, up to 3.5 mm per tooth. • Profile Shaping With Very High Feed

Just as one material has replaced another in moulds for certain applications, there are numerous instances of one machining process being replaced by another, superior to the former in certain respects. One such is trochoidal milling, which has proved to be a more efficient and quicker (by some 30 percent) method of machining fillets, pockets, slots and grooves in moulds, as compared to conventional milling.

In trochoidal milling, however, the cutting tool moves about along a curved path, which in geometry could be termed as a ‘trochoid’ ie: the curve traced by a point within a rolling circle, which is not its centre, between the end-points specified in the CNC program. The ‘step formation’ typical of the conventional milling method, is not characteristic of trochoidal milling,

and manual polishing which accounts for a significant portion of machining time in conventional milling, is almost entirely dispensable.

Software Solutions

Software is now a major component in the mould and die process. There are many CAD/CAM software suppliers in the market today, distinguished from one another by the features they provide, as well as by the nature of the after-sales service that is extended to the clients in the global market.

Vero International, NC Graphics and Delcam all have a strong presence in the die/mould sector; in fact, a majority of their clients belongs to this sector. Vero International Software’s VISI-series CAD/CAM software has recently been upgraded to include applications for 3D component design, plastic mould tool design, sheet metal tool design, progressive die design, 2D CAM, 3D CAM, continuous 5-axis machining, wire EDM and high speed milling. The 5-axis machining module enables the spindle (and a short tool) to be inclined to reach otherwise inaccessible nooks and crannies inside the mould – deep cavities and small radii. This spindle-adjustability obviates the need for tool extensions or longer tools, which would involve problems of deflection and poor surface finish.

The Message: Get Integrated

Early this year, a pan-European team working on a two-year, EU-sponsored project, emould@work, which attempted to find out what ailed the die/mould makers in the EU, published its findings, after studying the operations at several units.

Stuart Watson of Delcam, the Project Leader summarised the findings of the team for MEN:

creates a lot of idle time.

In a nutshell, it is not enough if the mould machining department is well equipped with the best CNC machines and highspeed

cutting tools. The design stage has to be seamlessly integrated into the manufacturing stage.

The suggestions of the emould@work project team can be extended to the other parts of the world. If there is a difference, it would just be a matter of degree.

High Technology = High Risk for Mankind

For about the past 40 years, people have been arguing about what to do with radioactive waste. Since the waste is harmful to humans—as well as to the environment— deciding where to put it is a serious problem.

Protection for 10 000 years

As radioactive isotopes decay, nuclear waste emits all common forms of radioactivity-alpha-particles, beta-particles, gamma-radiation, and X rays. When this radiation penetrates living cells, it knocks electrons away from atoms, causing them to become electrically charged ions. As a result, vital biological molecules break apart or form abnormal chemical bonds with other molecules. Often, a cell can repair this damage, but if too many molecules are disrupted, the cell will die. This ionizing radiation can also damage a cell's genetic material (DNA and RNA), causing the cell to divide again and again, out of control. This condition is called cancer. Because of these hazards, nuclear waste must be sealed and stored until the radioactive isotopes in the waste decay to the point at which radiation reaches a safe level. Some kinds of radioactive waste will require safe storage for at least 10 000 years.

Questions of disposal

Low-level waste includes materials from the nuclear medicine departments at hospitals, where radioactive isotopes are used to diagnose and treat diseases. The greatest disposal problem involves high- 892 level waste, or HLW. Nearly all HLW consists of used fuel rods from reactors at nuclear power plants; about a third of these rods are replaced every year or two because their supply of fissionable uranium-235 becomes depleted, or spent. When nuclear power plants in the United States began operating in 1957, engineers had planned to reprocess spent fuel to reclaim fissionable isotopes of uranium and plutonium to make new fuel rods. But people feared that the plutonium made available by reprocessing might be used to build bombs, so that plan was abandoned. Since that time, HLW has continued to accumulate at power plant sites in "temporary" storage facilities that are now nearly full. When there is no more storage space, plants will have to cease operation. Consequently, states and utility companies are demanding that the federal government honor the Nuclear Policy Act of 1982 in which the federal government agreed to provide permanent storage sites.

Low-level waste includes materials from the nuclear medicine departments at hospitals, where radioactive isotopes are used to diagnose and treat diseases. The greatest disposal problem involves high- 892 level waste, or HLW. Nearly all HLW consists of used fuel rods from reactors at nuclear power plants; about a third of these rods are replaced every year or two because their supply of fissionable uranium-235 becomes depleted, or spent. When nuclear power plants in the United States began operating in 1957, engineers had planned to reprocess spent fuel to reclaim fissionable isotopes of uranium and plutonium to make new fuel rods. But people feared that the plutonium made available by reprocessing might be used to build bombs, so that plan was abandoned. Since that time, HLW has continued to accumulate at power plant sites in "temporary" storage facilities that are now nearly full. When there is no more storage space, plants will have to cease operation. Consequently, states and utility companies are demanding that the federal government honor the Nuclear Policy Act of 1982 in which the federal government agreed to provide permanent storage sites.Disposal possibilities

Any site used for disposal of HLW must be far away from population centers and likely to remain geologically stable for thousands of years. One possibility lies at certain deep spots of the oceans, where, some scientists claim, the seabed is geologically stable as well as devoid of life. Sealed stainless-steel canisters of waste could be packed into rocket-shaped carriers which would bury themselves deep into sediments when they hit the ocean bottom. Opponents say that the canisters have not been proven safe and that, if released, the radioactivity could kill off photosynthetic marine algae that replenish much of the world's oxygen. Proponents claim that the ocean bottom already contains many radioactive minerals and that the radioactivity from all HLWs in existence would not harm marine algae. Scientists in the United States have considered other proposals as well, but since the Nuclear Policy Act of 1982, most of the attention has focused on the development of a disposal site beneath Yucca Mountain in Nevada. The design of this site includes sloping shafts that lead to a 570 hectare A400 acre) storage area 300 m deep in the mountain's interior. The U.S. Department of Energy is committed to developing Yucca Mountain. Engineers believe that it will be 2010 before the site is ready to receive waste. Until that time, there is a plan to begin moving HLW from power plants to a remote interim site in a western state. HLW would be transported to the storage site by truck or rail in sealed, steel canisters placed inside reinforced shipping casks.

Objections to Yucca Mountain

There are two main sources of opposition to the Yucca Mountain plan. One source maintains that Yucca Mountain has not been proven to be geologically secure, citing evidence that gases emitted at the lowest depth were able to reach the outside air. In addition, the group is concerned about the possibility of collisions or other accidents that might break the casks open while in transport. The Department of Energy claims it has proven the casks safe. Several tests have been performed, including one in which a cask was loaded onto a flatbed trailer and crashed into a concrete wall at 135 km/h. In another test, a cask was struck by a locomotive at 130 km/h. No leakage occurred in these tests. The other source of opposition to Yucca Mountain are people who maintain that the costs of overcoming legal challenges will ultimately make the plan financially infeasible. These people believe that the government should stop spending money on the Yucca Mountain project and resume the plan to reprocess waste to make new nuclear fuel.

Conclusion

Like I said on previous page. The bad thing we can't throw away as easy as we can imagine. We must face it and try to build a good thing for next.

Perspectivity of Nuclear Reaction

Stable nuclei can be made unstable

When a nucleus is bombarded with energetic particles, it may capture a particle, such as a neutron. As a result, the nucleus will no longer be stable and will disintegrate. For example, protons can be released when alpha particles collide with nitrogen atoms, as follows:

According to this expression, an alpha particle (4He) strikes a nitrogen nucleus ( 14N) and produces an unknown product nucleus (X) and a proton (1H). By balancing atomic numbers and mass numbers, we can conclude that the unknown product has a mass number of 17 and an atomic number of 8. Because the element with an atomic number of 8 is oxygen, the product can be written symbolically as 170, and the reaction can be written as follows:

This nuclear reaction starts with two stable isotopes—helium and nitrogen— that form an unstable intermediate nucleus (18F). The intermediate nucleus then disintegrates into two different stable isotopes, hydrogen and oxygen. This reaction, which was the first nuclear reaction to be observed, was detected by Rutherford in 1919.

Nuclear fission occurs when a heavy nucleus splits into two lighter nuclei. For fission to occur naturally, the nucleus must release energy. This means that the nucleons in the daughter nuclei must be more tightly bound and therefore have less mass than the nucleons in the parent nucleus. This decrease in mass per nucleon appears as released energy when fission occurs, often in forms such as photons or kinetic energy of the fission products. Because fission produces lighter nuclei, the binding energy per nucleon must increase with decreasing atomic number. Figure 25-8 shows that this is possible only for atoms in which A > 58. Thus, fission occurs naturally only for heavy atoms.

The isotope 236U* is an intermediate state that lasts only for about 10 -12 s before splitting into X and Y. Many combinations of X and Y are possible. In the fission of uranium, about 90 different daughter nuclei can be formed. The process also results in the production of about two or three neutrons per fission event. A typical reaction of this type is as follows:

To estimate the energy released in a typical fission process, note that the binding energy per nucleon is about 7.6 MeV for heavy nuclei (those having a mass number of approximately 240) and about 8.5 MeV for nuclei of intermediate mass (see Figure 25-8 ). The amount of energy released in a fission event is the difference in these binding energies (8.5 MeV - 7.6 MeV, or about 0.9 MeV per nucleon). Assuming a total of 240 nucleons, this is about 220 MeV. This is a very large amount of energy relative to the energy released in typical chemical reactions. For example, the energy released in burning one molecule of the octane used in gasoline engines is about one hundred-millionth the energy released in a single fission event.

Neutrons released in fission can trigger a chain reaction

When 235U undergoes fission, an average of about 2.5 neutrons are emitted per event. The released neutrons can be cap- captured by other nuclei, making these nuclei unstable. This triggers additional fission events, which lead to the possibility of a chain reaction, as shown in Figure 25-9. Calculations show that if the chain reaction is not controlled—that is, if it does not proceed slowly—it could result in the release of an enormous amount of energy and a violent explosion. If the energy in 1 kg of 235U were released, it would equal the energy released by the detonation of about 20 000 tons of TNT. This is the principle behind the first nuclear bomb.The first nuclear fission bomb, often called the atomic bomb, was tested in New Mexico in 1945.

When 235U undergoes fission, an average of about 2.5 neutrons are emitted per event. The released neutrons can be cap- captured by other nuclei, making these nuclei unstable. This triggers additional fission events, which lead to the possibility of a chain reaction, as shown in Figure 25-9. Calculations show that if the chain reaction is not controlled—that is, if it does not proceed slowly—it could result in the release of an enormous amount of energy and a violent explosion. If the energy in 1 kg of 235U were released, it would equal the energy released by the detonation of about 20 000 tons of TNT. This is the principle behind the first nuclear bomb.The first nuclear fission bomb, often called the atomic bomb, was tested in New Mexico in 1945. A nuclear reactor is a system designed to maintain a controlled, self- sustained chain reaction. Such a system was first achieved with uranium as the fuel in 1942 by Enrico Fermi, at the University of Chicago. Primarily, it is the uranium-235 isotope that releases energy through nuclear fission. Uranium from ore typically contains only about 0.7 percent of 235U, with the remaining 99.3 percent being the 238U isotope. Because uranium-238 tends to absorb neutrons instead of undergoing fission, reactor fuels must be processed to increase the proportion of 235U so the reaction can sustain itself. This process is called enrichment. At this time, all nuclear reactors operate through fission. One difficulty associated with fission reactors is the safe disposal of radioactive materials when the core is replaced. Transportation of reactor fuel and reactor wastes poses safety risks. As with all energy sources, the risks must be weighed against the benefits and the availability of the energy source.

Fusion reactors are being developed

2009-04-01

CAMCAD WorkNC

In this scenario, tasks are distributed to wherever they provide the most value to the manufacturer, which means that departments within the same company may be hundreds or even thousands of miles apart. In this type of distributed work environment, manufacturers expect software companies to provide solutions that work regardless of where their employees, subcontractors or manufacturing plants are located.

New advances in machine tool technology have also kept the CAM industry on its toes. The complexity of these machines requires advanced technology to program them efficiently and simulate all aspects of the machine motion.

Global Manufacturing Is Changing the Way CAM Software Is DevelopedNew manufacturing requirements are forcing CAM companies to take a closer look at their software development processes and sales distribution networks in order to deliver their products and software support to all countries where manufacturing plants are located.

For smaller CAM companies, these harsh new realities have forced some to recognize that they simply cannot afford to provide this type of global support. For larger companies with already hefty marketing and distribution budgets, it may not be feasible to increase development costs to gain access to niche markets in specific countries. This has led to increased CAM industry consolidation, where a larger company with a well-established global network acquires a smaller company that produces an excellent product in a specific niche.

The popularity of multi-task machines is due in large part to their ability to fully machine a variety of parts in a single setup. The complexity of programming these machines is easily handled in the latest CAM systems.

More Emphasis on Reliability and SpeedCAM customers fall into two broad groups: those who need to produce CNC programs as quickly as possible and those who need to produce CNC code that machines as efficiently as possible. In either case, users are increasing their demand for more reliable code. CAM developers are putting more consideration into making their systems easier to use, but the real emphasis has been on generating more efficient code that shaves seconds and minutes from every machining cycle.

CAM developers realize that a slick interface makes their system easier to sell, but the real bread and butter for any shop is producing parts as quickly and reliably as possible. To improve profitability for their customers, CAM companies have decided to allocate the majority of their development resources to improving cycle speeds and software quality while taking into consideration the overall user experience as an added bonus.

As the complexity of machine tools continues to increase, the ability to accurately simulate all machine motion has gained critical importance to avoid costly mistakes on the shop floor.

Hard Milling and High-Speed MachiningTraditional CAM toolpaths are the bane of high-speed machining because they allow sharp changes in tool direction, which require sharp reductions in the feedrate to avoid tool breakage. To eliminate this problem, CAM companies have developed specialized toolpaths that use mathematical algorithms to calculate the shape of cutter paths based on maintaining a constant cutter load. This is accomplished by analyzing the amount of material in contact with the tool at any given time and adjusting the cutting path to prevent the tool from ever becoming overengaged. These new toolpaths are particularly well-suited to machining hardened materials, parts with thin walls where tool pressure becomes a factor, and for utilizing the full capabilities of high-speed machining centers.

Although these advanced algorithms were developed for high-speed machines, they’ve proven very beneficial to all machine shops regardless of the type of CNC machines they currently have on the floor. A constant cutter load produces less pressure and vibration from the tool, which not only supports faster feedrates and faster spindle speeds—at greater depths-of-cut than traditional toolpaths—but also extends tool life and machine life as well.

Hard milling presents unique challenges to tool- and diemakers. The majority of this mold was milled using a short tool and three-axis strategies. The CAM system identified all areas of the toolpath where the tool couldn’t reach and easily converted those sections to five-axis toolpath.

For hard milling applications, companies are using shorter tools to improve rigidity. The problem is that these tools cannot reach into deep cavities. Some CAM companies have resolved this issue by allowing the user to cut as much of the toolpath as possible with three-axis milling strategies. When the software senses a tool or holder collision, the toolpath can be split and converted to a five-axis cutter path.

Programming for Multi-Task MachinesMulti-task machines that combine milling and turning on multiple spindles and multiple turrets with live tooling have become far too complex to program manually. Advanced CAM technology now offers better support for multi-axis, multi-spindle and multi-turret machines to get the most out of these investments. This is largely due to the partnerships that CAM developers have forged with machine tool builders so that CAM technology can be developed in step with machine tool advancements.

Realistic Machine SimulationWith so many moving components on new machine tools, particularly multi-task machines, it has become critically important to simulate every aspect of a machining operation to ensure that machine components, tools and parts don’t collide.

Many CAM systems now support the simulation of all machine movement, not just the part, tool and toolholder. Solid models are used for any machine component the user wants to simulate, with each assigned a type of movement: fixed, linear (X, Y, Z), or rotary motion (A, B, C). Motion for each component also can be defined in relation to other components. For example, it’s possible to define a turret with the B-axis mounted on an X-axis mounted on a Y-axis mounted on a Z-axis.

Industry Consolidation Will ContinueAs the CAM industry continues to mature, more consolidation will take place. Only companies with a worldwide distribution and support network will be able to survive. CAM companies will continue to focus their development efforts in specific niche markets where they can outshine the competition and increase collaboration with other software developers to reduce development costs.

It’s a more effective business strategy to license or purchase specific technology that’s already been developed by experts than it is to develop everything in-house. That way, a customer can pick and choose the right solutions for their manufacturing environment and purchase them all from the same vendor.

The result of this consolidation and collaboration is a better focus on specific industries such as molds, progressive dies and others. This provides a single point of contact for software support. Stronger partnerships with CAD companies, machine tool builders, cutting tool manufacturers, and machine controllers help everything work together as new technology is developed.

2009-03-30

Thinwall Molding Plastic

When I was a worker at PT Nagai Plastic Indonesia, we produce printer part for PT Epson Indonesia. We are specialize in big part such as housing, coverprinter, paper support and stacker paper. Our facility has 80 Ton till 960 Ton injection machine and as a Maintenance Supervisor, I have to keep that facility work well everytime.

These parts has thinner wall section almost every section. Especially on the rib. Many rib for wall part support. Off course many problem appear. But many merit too. Lighter, smaller parts molded with less resin and fastercycle times are being produced which translate into lower unit costs for themolder. However, these products require higher viscosity engineering polymers such as PC, ABS, and PC/ABS blends, which raises new challenges. Part design,resins, processing, and molding equipment are all impactedand there is a need for boosting performance requirements to meet the high speeds and pressuresdemanded. New hot runner designs play a key role.

Thinwall molding can be defined as either wall sections of less than 1.5 mmor flow length over wall thickness ratios (L/T) of greater than 100. By eithermeasure, thinwall molding pushes conventional molding equipment to the limitby its effect on the flow area as shown in the following example.

Flow path for thinwall molding is 1/10th that of conventional molding

The nominal wall thickness of conventional vs. a thinnwall design are 3.0 mm and 0.75 mm, respectively.In both cases as the molten resin travels throughthe mold, a skin layer is formed approximately 0.25 mm thick immediately atthe mold wall. The resulting flow paths are cut to 2.5 mm for the conventionalmolding and 0.25 mm for thinwall. Reducing the thinwall flow area to just one-tenth that of conventional molding can push standard molding equipment beyond its limits.

The high injection speeds and pressures employed in thin wall molding to overcome this reduced flow path narrow the process window, but higher performance equipment widens the window sufficiantly to produce precision parts. In order to produce thinwall parts, an injection molding must be able to meet these three requirements :

- High injection speeds and pressures;

- Rugged large clamp/small injection unit combination;

- High performance controls and hydraulics.

Fill times of less than 0.5 s are typical in thinwall molding in order to fillthe mold before the skin layer builds up and blocks the flow channel.An injection unit equipped with an accumulator can achieve such rapid fill times. The accumulator allows for near instantaneous delivery of a largevolume of oil to the injection cylinder during fill. The accumulator shouldbe located as close as possible to the injection cylinder in order to minimize pressure drop and maximize responsiveness. This also reduces the amount of fittings and hoses which are a potential source of leakage.

2009-03-28

Machine Tool

A machine tool is a powered mechanical device, typically used to fabricate metal components of machines by the selective removal of metal. The term machine tool is usually reserved for tools that used a power source other than human movement, but they can be powered by people if appropriately set up. Many historians of technology consider that the true machine tools were born when direct human involvement was removed from the shaping or stamping process of the different kinds of tools. For instance, they consider that lathe machine tools were invented around 1751 by Jacques de Vaucanson because he was the first to mount the cutting instrument on a mechanically adjustable head, taking it out of the hands of the operator.

A machine tool is a powered mechanical device, typically used to fabricate metal components of machines by the selective removal of metal. The term machine tool is usually reserved for tools that used a power source other than human movement, but they can be powered by people if appropriately set up. Many historians of technology consider that the true machine tools were born when direct human involvement was removed from the shaping or stamping process of the different kinds of tools. For instance, they consider that lathe machine tools were invented around 1751 by Jacques de Vaucanson because he was the first to mount the cutting instrument on a mechanically adjustable head, taking it out of the hands of the operator.Machine tools can be powered from a variety of sources. Human and animal power are options, as is energy captured through the use of waterwheels. However, machine tools really began to develop after the development of the steam engine, leading to the Industrial Revolution. Today, most are powered by electricity.

Machine tools can be operated manually, or under automatic control. Early machines used flywheels to stabilize their motion and had complex systems of gears and levers to control the machine and the piece being worked on. Soon after World War II, the NC, or numerical control, machine was developed. NC machines used a series of numbers punched on paper tape or punch cards to control their motion. In the 1960s, computers were added to give even more flexibility to the process. Such machines became known as CNC, or computer numerical control, machines. NC and CNC machines could precisely repeat sequences over and over, and could produce much more complex pieces than even the most skilled tool operators.

Before long, the machines could automatically change the specific cutting and shaping tools that were being used.

Today, it is possible to design a complex part on a computer, put a bar or rod into a machine center, and have a finished part within a matter of minutes.

- - Drill (like mill, but optimized to make holes)

- - Gear shaper

- - Hobbing machine

- - Lathe (work rotates, single-edge cutter is fixed)

- - Milling machine (work is fixed, multi-edge cutter rotates)

- - Shaper Stewart platform mills

- - Grinders

- EDM (electrical discharge machining)

- Grinding

- Multiple edge cutting tools

- Single edge cutting tools

Other techniques are used to add desired material. Devices that fabricate components by selective addition of material are called rapid prototyping machines.

Workshop with various Machine Tool

High Tech 5 Axis Machine

2009-03-20

Bench Work Practice

2009-03-15

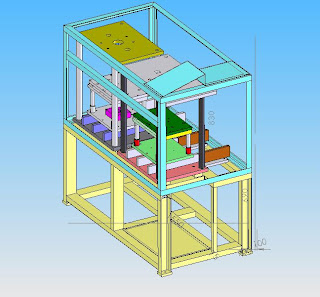

Leak Test Machine

1. Chemical plant

Once ago we build a Leak Test Machine for Suzuki Motor Corp, for testing leakageon theirs part Cylinder Head Motor (combustion chamber and exhaust system).We make machine base,jig and mechanic parts.

2009-03-12

Knuckle Washing Machine

I'm not realize how important cascade method to solve pneumatic problem untill i have a case . While ago i'm just ordinary student on Swiss Project in Politechnic for Mechanicin Bandung. I like technic but for study theoritically that a part i'm too lazy for. When i follow pneumatic lesson i like it but theoritically i don't catch it too much.

Eleven years later i must open my pneumatic book again.

My customer Tsuzuki Asama need a washing machine to wash off the car's component name is knuckle.After pass several cnc machine process that part must be washed through water contain anti rust agent. The part put in tray and that tray is moving up and down actionmoved by pneumatic cylinder.They want that machine is fully pneumatic without electric component.

Here is the challenge.

The action can be controlled, timing, how many times up and down action how deep is down level and other thing without use PLC.That is easy for professional but for me..feuwww.I try to design pneumatical scheme for that and try and try again. But stillcan not work. Then i open my lesson book about automation. I read again because already 11 years ago that i never read it well. And then i found about cascade method but still i can't understand it. After read well in a hour i found usage of motion diagram and control diagram are solve my problem.

2009-03-11

Ceramic Component

My friend need component made by ceramic, because he try many

2009-03-07

3D Design Interior and Animate It

Build a house or a construction site need good planning if not after finish it

we realize that is not our want.And if we want some modification or rebuilt

is not as simple as we make something like make castle from sand in the

beach.It need high investment. We can build it first in 3D design so we can

look around observe our design then we can make some modification or

redesign again if we don't want it.We can try various texture for our wall,

roof or furniture inside it.After we satisfy with our design , then the

construction company do the rest.

This design request by Indofood Corp to make meeting room in their office.

We can explore every detail of our room's design.

With 3D design software we can build everything in virtual dimension.

Try it!Its fun.