Leak Test Machine is used for showing any leaking on the component or sub assy component.Leakage is a process in which material is lost, intentionally or accidentally, gradually through the holes or defects of their containers. The material lost is usually fluid, usually liquid or powder and sometimes gas, from an imperfectly sealed container Many industries use this equipment for their component;

1. Chemical plant

1. Chemical plant

2. Petrochemical plant: hydrocracker, vapocracker, catalytic reforming, steam reforming are all Hydrogen based processes were Hydrogen leak testing will be very appropriate,

3. Semiconductor industry; all processes taking place in a process chamber at atmospheric pressure or under vacuum; Diffusion, Oxidation, LPCVD, PECVD, PVD, Etch, Ion Implant, typically the later that implies vacuum will require Helium leak testing, while the other will make good use of Hydrogen leak testing,

4. Automotive: with airbag being the most demanding leak testing application (small gas tank, very high pressure, long shelf life) and air conditioning system (for best efficiency), fuel system (for low emission), exhaust system (for lowest pollution), engine and transmission (for no oil dripage), rims to keep tyre safe,

5. Medical: to ensure safe and long life implant (pacemaker) or a safe catheter

6. Airplane: to quickly and safely locate fuel leaks , to check oxygen distribution devices and cabin pressurization systems

7. Refrigeration and air conditioning systems-residential, commercial or industrial- in order to deliver best efficiency at the lowest loss rate of refrigerant gases (ozone depletion)

8. Power distribution for high voltage circuit breaker using SF6 as a dielectric

9. Drinking water distribution grid as today average leakage rate or efficiency is above 25%, wasting precious resources, water and power.

10.Sewage water collecting network as leaks can contaminate drinking water collection process;

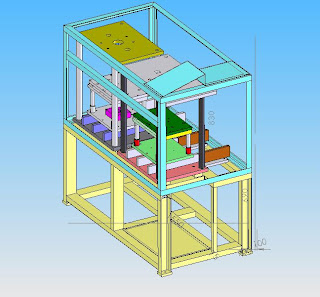

Once ago we build a Leak Test Machine for Suzuki Motor Corp, for testing leakageon theirs part Cylinder Head Motor (combustion chamber and exhaust system).We make machine base,jig and mechanic parts.

For electric parts we use branded part as Fuji,Mitsubishi for PLC, Cosmo for Leakage Main Control,etc.

For pneumatic parts we use Festo Indonesia's parts. After we assemble all together, the system doesn't work. We doing check the control system or the cylinder head part is not good. Finally we find error in the control system. We change the pneumatic parts from Festo to SMC especially the micro valve then the system work well. But this cut US$ 3000 my profit.

tos...biasa pikir2

ReplyDeleteI'm interested to your leak test machine and your article.

ReplyDeleteHow can I get your contact number ?

Regards

Imel - Bandung

Pharmaceutical company

Thank u for your interest. You can contact us at ptfaeng@gmail.com , 62 22 91324451 , 62 818436859. Our workshop in Bandung too, Jl. adipati ukur no.3 bale endah.

ReplyDeleteSee you soon.

Hi, This leak test machine is looking appropriate for testing. Can you provide more specifications. Thank you.

ReplyDelete